Preventive measures against breaking of self drilling screws

Fracture for broken cap, broken tail, broken rod, often occurs in martensitic carbon steel self drilling screw, martensitic carbon steel self drilling screw through high temperature carbonitriding surface hardness reached ≥560HV, with strong penetration, but also increased the brittleness of the screw.When the self drilling screw in the case of excessive load, excessive torque, easy vibration will occur brittle fracture phenomenon.When the self drilling breaks, it will not only affect the construction progress, not beautiful, but also bring a series of safety hazards.There are mainly the following aspects to prevent the breakage of drilling screw:

1: Choose the right product

a: Before use, confirm whether the mechanical properties of the product can meet the requirements of use

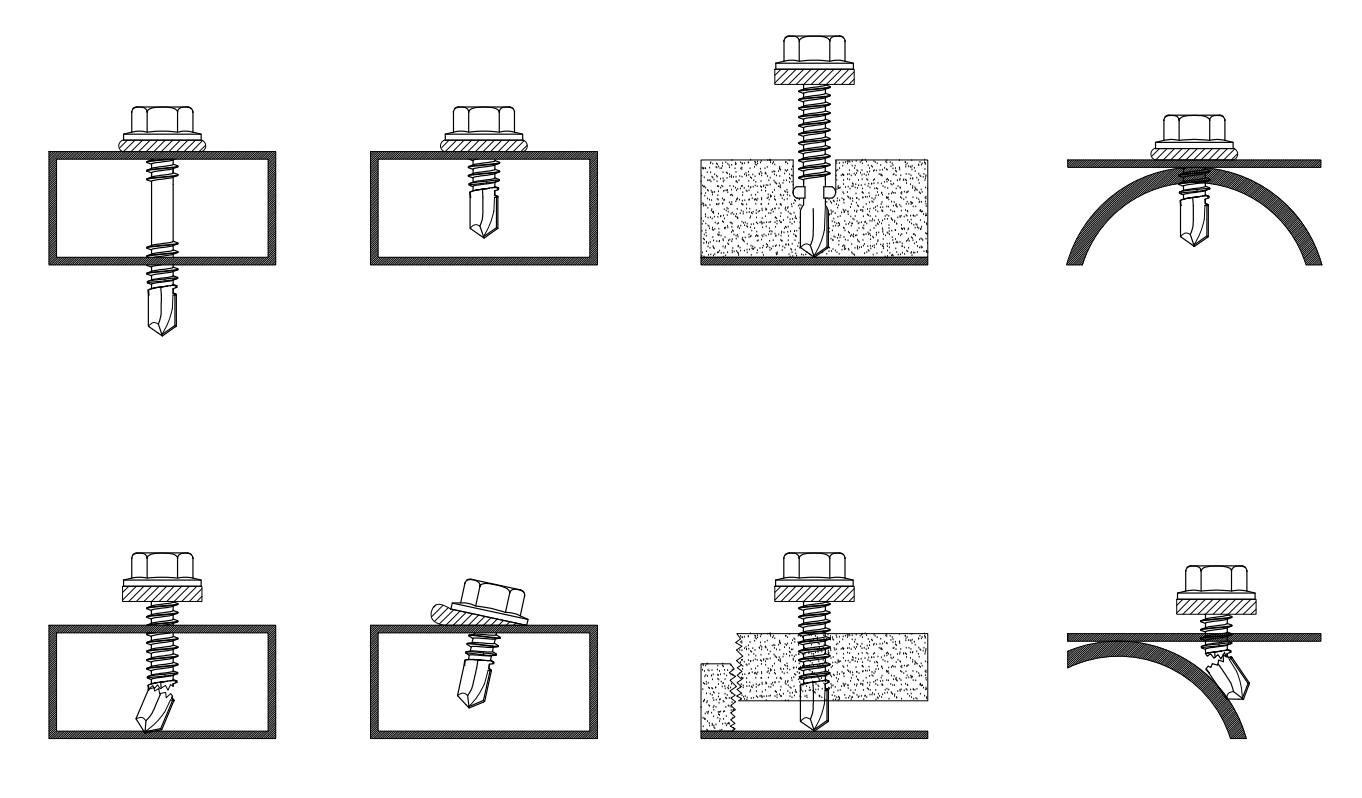

b: Reasonable selection of screw size and length

C: It is recommended to use half tooth or double tooth product in interlayer environment

2: Use the number

A: Use 4-6 screws per square meter

B: The number of roof and heavy plate should be increased appropriately

C: Wind area is larger appropriate increase dosage

3: Correct use method

A: Tap perpendicular to the axis of the thread, do not tilt

B: In the tightening process, the force must be uniform, and the tightening torque should not exceed the safety torque

C: 12#, 14# specification products, electric drill speed 1000-1800 revolution can not be too fast

4: Failure torque (below data for reference only) unit: N.m

|

specifications |

Destroy the torque min |

|

4# |

1.5 |

|

6# |

2.8 |

|

8# |

4.7 |

|

10# |

6.9 |

|

12# |

10.4 |

|

14# |

16.9 |