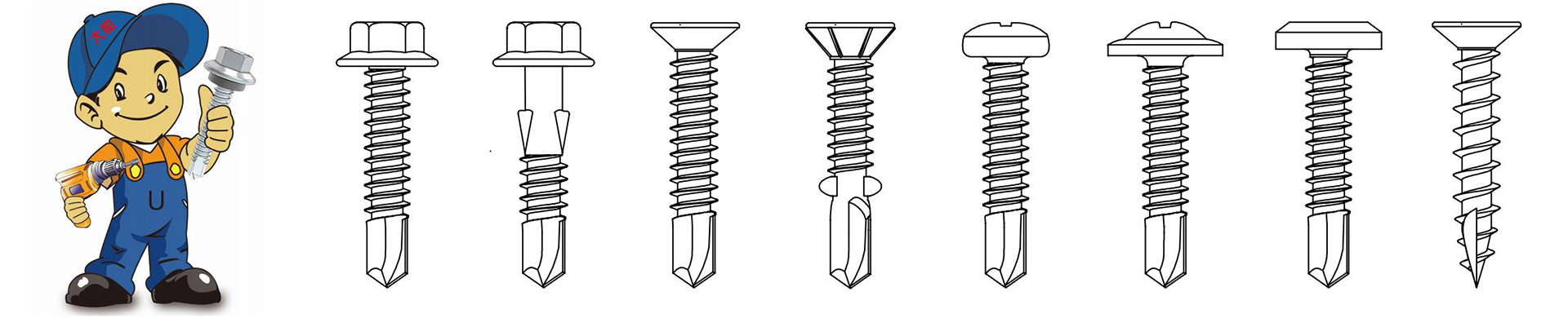

Low MOQ for Fine Thread Self Tapping Screws - Truss head Self-Drilling Screws – DaHe

Low MOQ for Fine Thread Self Tapping Screws - Truss head Self-Drilling Screws – DaHe Detail:

A fastener with an extra wide head, twinfast thread and self drilling point. The head is an integrally formed round washer with a low rounded top that is approximately 75% the diameter of the washer. Material including:C1022 or equivalent steel and 410 stainless

C1022

Common usage is to attach wire or metal lathe to metal studs of a thickness between 12-20 gauge.the head design offers low clearance and an extra large bearing surface.the recommended drive speed for installation is 2500 rpm.

Heat Treatment:Screws shall be quenched in liquid and then tempered by reheating to 625゜F minimum.

Hydrogen embrittlement: Lustrate hydrogen after galvanizing to avoid hydrogen embrittlement(The production from DaHe company Only)

410 stainless

Not as corrosion-resistant as the 18-8 variety but will drill through harder materials than the 18-8 screw. The same hardness gradient rule applies: material drilled should be a minimum of 10-20 rockwell hardness points less than the fastener

Heat Treatment:An ideal method of hardening 410 stainless screws is a bright hardening process,which typically involves a vacuum furnace, Another key factor affecting hardness is the chemistry of the fastener–most elements have maximum values but not minimums.This fact can contribute to hardness variance.

Usually supplied without a secondary finish

Hydrogen embrittlement: there is not Hydrogen embrittlement risk occur

Note: there is no single standard for Truss head self-drilling screws.these values are offered as a guide, deviations from these specifications may occur

Specification

|

Brand |

Solidex |

|

Product Type |

Truss head Self-Drilling Screws |

|

Material |

Stainless steel/carbon steel |

|

Drive Type |

Phillips/Six-lobe drive |

|

Product Length |

5/8″-12″/1/4″ 3/8″ 7/16″ 1/2″ 9/16″ 5/8″ 3/4″ 7/8″ 1″ 1-1/8″ 1-1/4″ |

|

Screw Diameter (mm) |

6#/7#/8#/10#/12# |

|

Thread Length |

Fully Thread |

|

RoHS |

Depend on request |

|

Finish |

Clear Zinc/Customized different color |

|

Corrosion resistance class |

C3 |

|

Product Standard |

GB/DIN/ANSI/BS/JIS |

|

Approvals |

CE |

|

Packing |

Coustomer’s Requirements |

|

OEM |

Accept customization |

|

Sample |

Free |

|

Place of Origin |

Hebei, China |

|

Suitable Use Type |

Suitable for indoor Use |

|

Manufacturer Guarantee |

1 Year Guarantee |

|

Supply Ability |

100 Ton/Tons per Day |

NOTE:

1: Drill Capacity: 8g (0.75-2.5mm of steel), 10g (0.75-3.5mm of steel)

2:Driver Type: Philips P2

3:Installation Speed: 2300-2500 RPM Max Drill Speed

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Low MOQ for Fine Thread Self Tapping Screws - Truss head Self-Drilling Screws – DaHe , The product will supply to all over the world, such as: Belgium, Spain, Florida, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable products quality , increase customers' satisfaction and achieve win-win situation .

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.