Popular Design for Industrial Fasteners - Aluminum Body/Steel Mandrel Dome Head Break-Stem Blind Rivets – DaHe

Popular Design for Industrial Fasteners - Aluminum Body/Steel Mandrel Dome Head Break-Stem Blind Rivets – DaHe Detail:

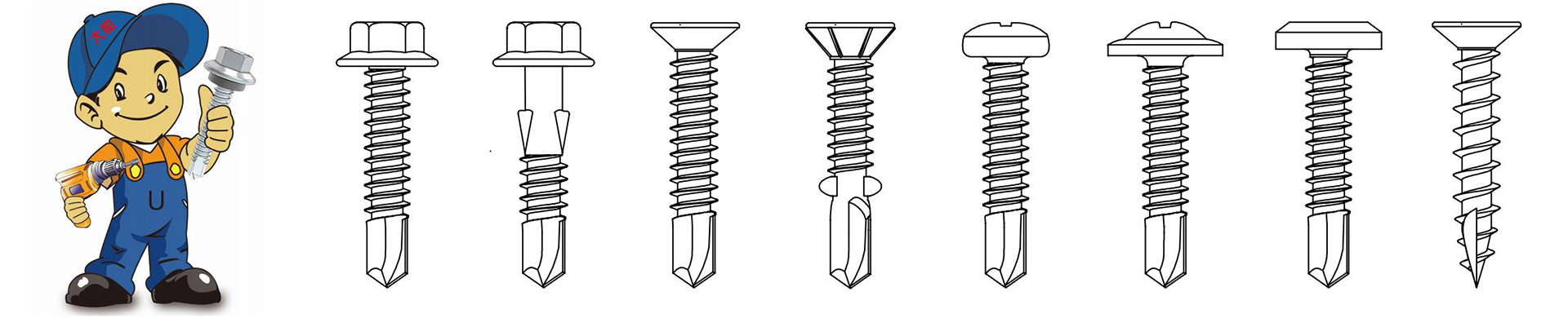

Blind Rivets are available in various combinations of aluminum, stainless steel and steel. Offered in standard dome, large flange, countersunk and closed end head styles, blind rivets feature a mandrel which is pulled through the body. This action expands the blind end of the rivet shank, creating a permanent hold. Required grip range is based on the thickness of the materials that are being joined together.

An aluminum blind fastener which has a self-contained steel mandrel which permits the formation of an upset on the blind end of the rivet and expansion of the rivet shank during rivet setting to join the component parts of an assembly.The steel mandrel is pulled into or against the rivet body,breaking at or near the junction of the mandrel shank and its upset end.The head of the body is slightly rounded and twice as wide as the body diameter

Provide large secondary bearing surface ,Exceptional pull-up / clamp-up properties

Peel Blind Rivets are designed for improved support in brittle, soft, or ductile materials. The mandrel of peel rivets is designed to split the end of the rivet body into four separate legs to create a large blindside bearing surface.

We provide our customers high quality of blind rivet, which is designed employing exceptional quality material at progressive infrastructure facility.

Advantages: Dome head is the most commonly specified head style because of its low profile and neat, finish appearance. The steel mandrel gives this style rivet greater tensile and shear values than aluminum mandrels.The should be used when fastening materials with similar mechanical and physical properties

Application

1:Soft material such as wood

2:Plasterboard

3:Furniture

4:Plastic-framed window

Specification

|

Aluminum Body/Steel Mandrel Dome Head Break-Stem Blind Rivets SAE J-1200 |

||||||||||||

|

Nominal Rivet Diameter |

D |

H |

E |

W |

P |

F |

Ultimate Shear Load |

Ultimate Tensile Load |

Mandrel Break Load |

|||

|

Rivet Shank Diameter |

Head Diameter |

Head Height |

Mandrel Diameter |

Mandrel Protrusion |

Blind Side Production |

|||||||

|

Max |

Min |

Max |

Min |

Max |

Nom |

Min |

Max |

Min,lb. |

Min,lb. |

Max |

Min |

|

|

3/32 |

0.096 |

0.090 |

0.198 |

0.178 |

0.032 |

0.057 |

1.00 |

L+0.100 |

90 |

120 |

275 |

175 |

|

1/8 |

0.128 |

0.122 |

0.262 |

0.238 |

0.040 |

0.076 |

1.00 |

L+0.120 |

170 |

220 |

600 |

400 |

|

5/32 |

0.159 |

0.153 |

0.328 |

0.296 |

0.050 |

0.095 |

1.06 |

L+0.140 |

260 |

350 |

850 |

600 |

|

3/16 |

0.191 |

0.183 |

0.394 |

0.356 |

0.060 |

0.114 |

1.06 |

L+0.160 |

380 |

500 |

1050 |

750 |

|

1/4 |

0.255 |

0.246 |

0.525 |

0.475 |

0.080 |

0.151 |

1.25 |

L+0.180 |

700 |

920 |

1850 |

1450 |

Product detail pictures:

Related Product Guide:

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we're the lowest around for Popular Design for Industrial Fasteners - Aluminum Body/Steel Mandrel Dome Head Break-Stem Blind Rivets – DaHe , The product will supply to all over the world, such as: Oman, Bahrain, New York, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we've been likely to be pleased to serve you.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.