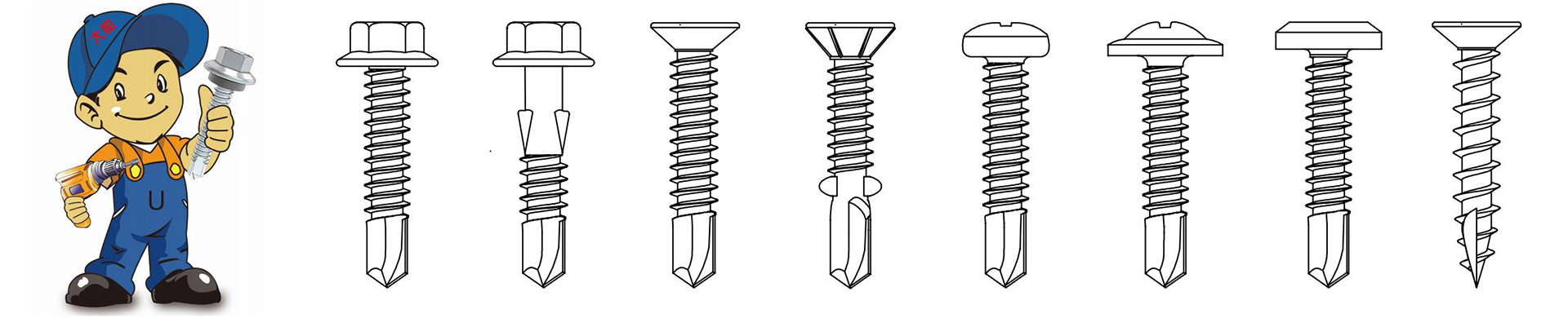

PriceList for Button Head Self Drilling Screws - Wafer head Self-Drilling Screws – DaHe

PriceList for Button Head Self Drilling Screws - Wafer head Self-Drilling Screws – DaHe Detail:

Wafer Head selfdrilling screw generally have two material: carbon steel and 410 stainless steel.

Wafer Head Self-drilling screw with reduced head height. This reduced head height gives it special characteristics:

1:Avoids interference with moving elements.For use in fixings where an even distribution of pressure is required, without the need for assembling additional flat washers, and without the head protruding excessively:

2: Aesthetic finish as screw is rounded and is concealed once installed.

3: May be used as a substitute for rivets.

4:Wide range of thicknesses to be drilled – from 0.70 mm to 4.40 mm.

5:Wide range of measurements.

6: Cone between thread and head to ensure piece sits perfectly.

Application

1: For fixing soft materials on metal (methacrylate, plastic, chipboard, thin metallic plates, etc)

2:For joints on metal which require a low head (sliding doors and windows, inlaid locks, etc.)

3:Reduced cone under head to improve finish on flat surfaces.

4:For joining metal to wood, joining metallic elements, or plastic, wood or other materials on metallic materials

Feature

1: Available in various coatings and colors upon request

2:May be used as a substitute for rivets in many applications, with the advantage of being removable.

3:Wafer head design on purpose

4:Non-walking point provides fast material engagement

Note

1: 410 Stainless steel wafer head self drilling screw for use exclusively with aluminium (does not produce corrosion by galvanic coupling). Do not use screw in stainless steel to drill steel, as point will burn out due to lack of hardness.

2:The choice of screw point must be such that the total thickness of materials to be joined (including any intermediate spaces) is lower than the edge of the drill point; otherwise screw breakage may occur during installation.

Specification

|

Brand |

DaHe |

|

Product Type |

Wafer head Self-Drilling Screws |

|

Material |

Stainless steel/carbon steel |

|

Drive Type |

Wafer head |

|

Product Length |

5/8″-12″/1/4″ 3/8″ 7/16″ 1/2″ 9/16″ 5/8″ 3/4″ 7/8″ 1″ 1-1/8″ 1-1/4″ |

|

Screw Diameter (mm) |

6#/7#/8#/10#/12#/14#* |

|

Thread Length |

Fully Thread |

|

Finish |

White Zinc/Ruspert/Customized |

|

Corrosion resistance class |

C3 |

|

Product Standard |

GB/DIN7ANSI/BS/JIS |

|

Approvals |

CE |

|

Packing |

Coustomer’s Requirements |

|

OEM |

Accept customization |

|

Place of Origin |

Hebei, China |

|

Suitable Use Type |

Suitable for indoor Use |

|

Manufacturer Guarantee |

1 Year Guarantee |

NOTE:

1: Drill Capacity: 8g (0.75-2.5mm of steel), 10g (0.75-3.5mm of steel)

2:Driver Type: Philips P2

3:Installation Speed: 2300-2500 RPM Max Drill Speed

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future jointly with your esteemed company for PriceList for Button Head Self Drilling Screws - Wafer head Self-Drilling Screws – DaHe , The product will supply to all over the world, such as: Azerbaijan, New Delhi, kazakhstan, We'd like to invite customers from abroad to discuss business with us. We can provide our clients with high quality products and excellent service. We are sure that we will have good cooperative relationships and make a brilliant future for both parties.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.