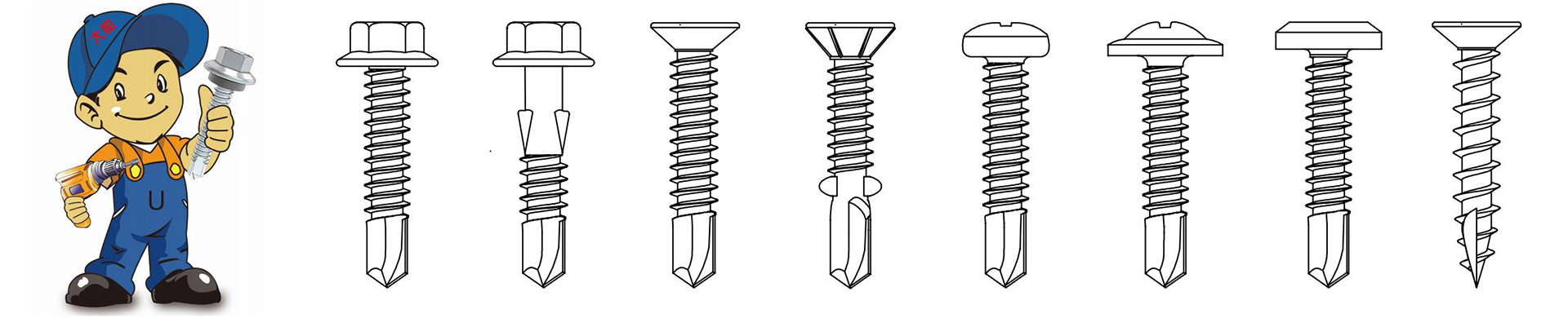

Professional Design Countersunk Self Drilling Screw - High-Low STS with ruspert coating – DaHe

Professional Design Countersunk Self Drilling Screw - High-Low STS with ruspert coating – DaHe Detail:

Ruspert treatment is a high-grade anti-corrosion metal surface treatment technology,Forming combined film by chemical reaction among each layers. It does not attribute its good anti-corrosion performance to merely a single film as ordinary metal surface treatment. It provide superior corrosion resistance by combined film.it consists of three layers:

‧A metallic zine layer

‧A high grade anti-corrosion chemical conversion film

‧A baked ceramic surface coating

The unique feature of Ruspert Coating is the tight joining of the baked ceramic top coating and the chemical conversion film thanks to the cross-linking effect. These layers are bonded together with the metallic zinc layer,through chemical reactions, and this unique method of combining layers results in a rigid and dense combination of the coating films.Greatly improve the anti-corrosion performance of traditional hot-dip galvanizing and electroplating. moreover,various colors can be provided to mathch the surrounding landscape.

Ruspert is a combination of electroplating and coating,which can be widely used in different conditions.

Features

1:superior corrosion resistance

A:Combined with zinc plating film such as electroplating which can improve anti-corrosion performance in different conditions

B:the chrome passivation treatment is changed to special chemical film,strong adhesion with topcoat can still hold the equivalent performance

2:corrosion resistance against scratches

Ruspert has high anti-corrosion performance against scratches due to the combined film

3:color variation

The basic color is silver,and if it is necessary, other colors are also available,please contact us in advance

4:Low cure temperature

There is no effects on physical properties of metal due to the low cure temperature below 200C

5:Electrolytic corrosion resistance

Reduce dissimilar metal contact corrosion apparently between the products and aluminum board or plated steel board

Specification

|

Brand |

DaHe Series |

|

Product Type |

High-Low STS with ruspert coating |

|

Material |

C1022 |

|

Drive Type |

Phillip |

|

Product Length |

5/8″– 2″ |

|

Screw Diameter (mm) |

6#–14#* |

|

Thread Length |

Fully Thread |

|

Washer |

– |

|

Finish |

Ruspert coating |

|

Corrosion resistance class |

C4 |

|

Product Standard |

DIN7504/ANSI/ISO |

|

Approvals |

CE |

|

Packing |

Coustomer’s Requirements |

|

OEM |

Accept customization according to client request |

|

Sample |

Free |

|

Place of Origin |

Hebei, China |

|

Suitable Use Type |

Suitable for Outdoor Use |

|

Manufacturer Guarantee |

2Year Guarantee |

|

Supply Ability |

100 Ton/ per Day |

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for Professional Design Countersunk Self Drilling Screw - High-Low STS with ruspert coating – DaHe , The product will supply to all over the world, such as: Romania, Cyprus, Oman, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!