Short Lead Time for Countersunk Self Drilling Screw - Chipboard Screws – DaHe

Short Lead Time for Countersunk Self Drilling Screw - Chipboard Screws – DaHe Detail:

Need quality chipboard screws? At DaHe, we understand that getting the job done well is benefits greatly from the use of high-quality materials.

And you need to use the right materials. For consumables, DaHe have the range and expertise to help you get any building job done. For different types of timber, there are different types of fasteners.

For very soft timbers, MDF or chipboard, you need to use chipboard screws.

Why? Well, have you ever tried to go on the cheap and use whatever you had lying around in the shed ‘just this time around’? Fine-thread screws from a previous job, perhaps? It’s understandable to want to save money, but you could end up spending more money in the long run after generic fasteners simply slide out of the hole and your project falls to bits.

Make the Right Choice

Chipboard screws feature a slim shank with a very coarse thread that digs deeper and more tightly into the timber. In other words, more timber or composite board is embedded in the thread, creating an extremely firm grip.

Fix chipboard sheets and other soft material to timber with a flush finish. Featured countersunk head with ribs on underside. The ribbed head assists with removal of chipboard particles to sink the head flush.

For external installation we recommend T17 Construction Screws – these can be used also in treated pine.

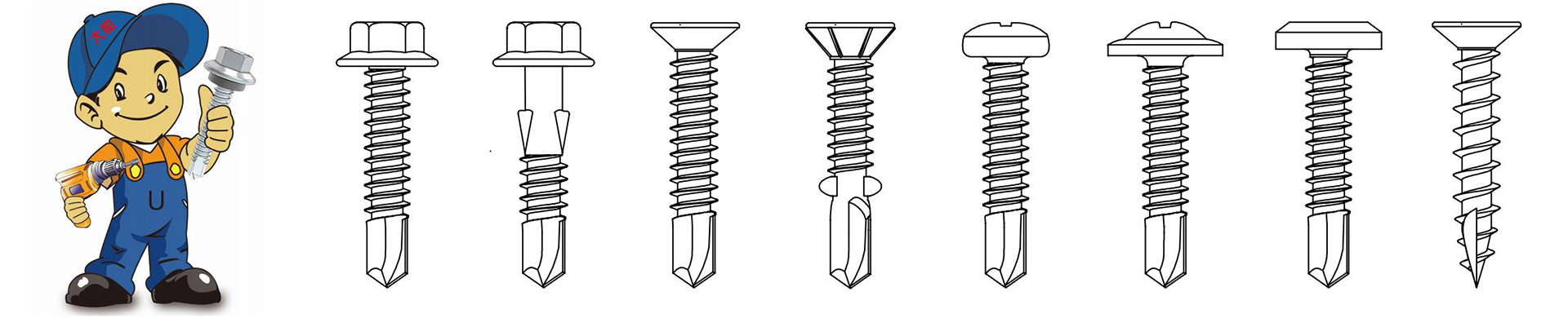

Chipboard Screws Types

Types: DaHe carry these products in essentially two finishes:

Zinc yellow-plated – standard-finish screw most suitable for indoor applications

Class 3 galvanised – specially-coated screw most suitable for outdoor applications and for chemically-treated softwood and soft composite boards

Specification

|

Brand |

Solidex |

|

Product Type |

Chipboard Screws |

|

Material |

carbon steel |

|

Drive Type |

Philips P2 |

|

Product Length |

1’—4’ |

|

Screw Diameter (mm) |

M4/M5/M6 |

|

Thread Length |

Fully Thread/Double Thread |

|

Point Type |

Needle |

|

Finish |

Yellow Zinc/Customized |

|

Head Type |

Countersunk |

|

Product Standard |

GB/DIN7ANSI/BS/JIS |

|

Approvals |

CE |

|

Drill Capacity |

Fix chipboard sheets and other soft material |

|

Sample |

Free |

|

Place of Origin |

Hebei, China |

|

Suitable Use Type |

Suitable for Outdoor Use |

|

Manufacturer Guarantee |

1 Year Guarantee |

|

Supply Ability |

50Ton/ Day |

NOTE:

1: Installation Speed: 2300-2500 RPM Max Drill Speed

Product detail pictures:

Related Product Guide:

Adhering into the basic principle of "quality, assistance, effectiveness and growth", we have attained trusts and praises from domestic and worldwide client for Short Lead Time for Countersunk Self Drilling Screw - Chipboard Screws – DaHe , The product will supply to all over the world, such as: Cannes, New York, Kenya, During in 11 years,We have participated in more than 20 exhibitions,obtains the highest praise from each customer. Our company always aim to provide the customer best products with lowest price. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. Join us, show your beauty. We will always be your first choice. Trust us, you will never lose heart.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.