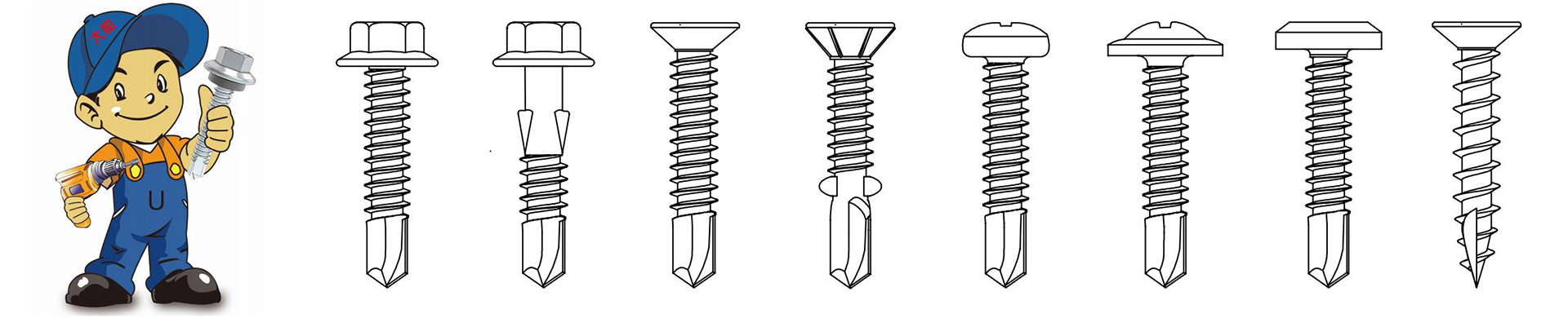

Short Lead Time for Countersunk Self Drilling Screw - Truss head Self-Drilling Screws – DaHe

Short Lead Time for Countersunk Self Drilling Screw - Truss head Self-Drilling Screws – DaHe Detail:

A fastener with an extra wide head, twinfast thread and self drilling point. The head is an integrally formed round washer with a low rounded top that is approximately 75% the diameter of the washer. Material including:C1022 or equivalent steel and 410 stainless

C1022

Common usage is to attach wire or metal lathe to metal studs of a thickness between 12-20 gauge.the head design offers low clearance and an extra large bearing surface.the recommended drive speed for installation is 2500 rpm.

Heat Treatment:Screws shall be quenched in liquid and then tempered by reheating to 625゜F minimum.

Hydrogen embrittlement: Lustrate hydrogen after galvanizing to avoid hydrogen embrittlement(The production from DaHe company Only)

410 stainless

Not as corrosion-resistant as the 18-8 variety but will drill through harder materials than the 18-8 screw. The same hardness gradient rule applies: material drilled should be a minimum of 10-20 rockwell hardness points less than the fastener

Heat Treatment:An ideal method of hardening 410 stainless screws is a bright hardening process,which typically involves a vacuum furnace, Another key factor affecting hardness is the chemistry of the fastener–most elements have maximum values but not minimums.This fact can contribute to hardness variance.

Usually supplied without a secondary finish

Hydrogen embrittlement: there is not Hydrogen embrittlement risk occur

Note: there is no single standard for Truss head self-drilling screws.these values are offered as a guide, deviations from these specifications may occur

Specification

|

Brand |

Solidex |

|

Product Type |

Truss head Self-Drilling Screws |

|

Material |

Stainless steel/carbon steel |

|

Drive Type |

Phillips/Six-lobe drive |

|

Product Length |

5/8″-12″/1/4″ 3/8″ 7/16″ 1/2″ 9/16″ 5/8″ 3/4″ 7/8″ 1″ 1-1/8″ 1-1/4″ |

|

Screw Diameter (mm) |

6#/7#/8#/10#/12# |

|

Thread Length |

Fully Thread |

|

RoHS |

Depend on request |

|

Finish |

Clear Zinc/Customized different color |

|

Corrosion resistance class |

C3 |

|

Product Standard |

GB/DIN/ANSI/BS/JIS |

|

Approvals |

CE |

|

Packing |

Coustomer’s Requirements |

|

OEM |

Accept customization |

|

Sample |

Free |

|

Place of Origin |

Hebei, China |

|

Suitable Use Type |

Suitable for indoor Use |

|

Manufacturer Guarantee |

1 Year Guarantee |

|

Supply Ability |

100 Ton/Tons per Day |

NOTE:

1: Drill Capacity: 8g (0.75-2.5mm of steel), 10g (0.75-3.5mm of steel)

2:Driver Type: Philips P2

3:Installation Speed: 2300-2500 RPM Max Drill Speed

Product detail pictures:

Related Product Guide:

With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we've earned an outstanding track record amongst our consumers across the whole world for Short Lead Time for Countersunk Self Drilling Screw - Truss head Self-Drilling Screws – DaHe , The product will supply to all over the world, such as: Naples, Senegal, Kuala Lumpur, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!